Did you know that people used to make asphalt manually when there were no mixing plants? It was a long and painstaking process that involved a lot of workers. But with the advent of asphalt mixing plants (асфальтные заводы), construction projects became a lot easier than before. It allowed construction workers to make high-quality asphalt within a few hours instead of relying on asphalt suppliers in the vicinity.

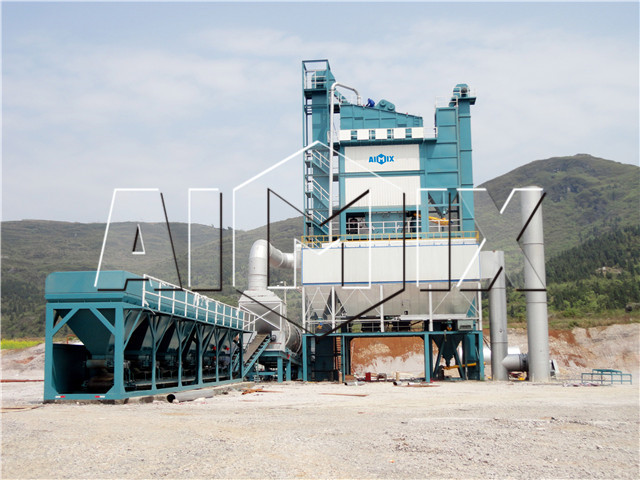

If you have a construction company, it is high time that you invest in an asphalt mixing plant. You will notice a significant difference in the time your workers take to complete the construction projects. These plants that come from China can measure the fillers, sand, and aggregates according to the quantities required, mix them in a rotating chamber, and produce high-quality asphalt without requiring too much help from workers.

Prices of Chinese asphalt mixing plants

The prices of Chinese asphalt mixing plants may vary from $500,000 to $4 million. The difference in price is due to the advanced features that high-end plants have. If you are looking for an asphalt mixing plant (асфальтовый завод) that can handle a huge quantity of ingredients, make sure you buy one that has the following features:

1. The mixing chamber should have metal blades. Metal blades are the best when it comes to mixing sand, fillers, and aggregates. Some plants cut down the cost by using aluminum blades. Although they may do the job for a few years, they are not long-lasting as metal. When metal blades operate at high speeds, they churn the aggregates thoroughly with other ingredients. The asphalt mixing plants from China ensures that the final output is smooth and doesn’t contain any lumps.

2. One of the most crucial parts of an asphalt mixing machine is the chamber that measures hot aggregate temperature. This chamber keeps measuring the real-time temperature of the mixture in the mixing drum. The mixer should churn the ingredients at a specific temperature to produce high-quality asphalt. This device is responsible for controlling the temperature inside that chamber.

3. The aggregates used in making asphalt contain small pieces of stones and rocks. These particles may accidentally enter the arching phase while the mixing chamber mixes the ingredients. The asphalt mixing plants from China (китайский асфальтобетонный завод) have a mineral filler silo to prevent these particles from entering the arching phase. It ensures that the arching phase works smoothly to produce high-quality asphalt by keeping the impurities away.

4. Another crucial part that contributes to the final price of the asphalt mixing plant is the dust collecting unit. Low-end plants don’t have this unit, and thus, they pollute the construction site. It is wise to invest in a plant that has a dust collecting unit so that your workers don’t get affected by the fillers ejected by the plant. Learn more: https://aimixmachinery.uz/kupit-asfaltnyy-zavod-tsena-nedorogaya-v-uzbekistane/.

You should compare the different features of asphalt mixing plants before investing in one. Set a budget and see which model has the best features within that limit. You can also wait for the brands to announce discount offers if you want to buy a high-end model at a budget-friendly price. If you want to buy asphalt mixing plants from China, Aimix Group is a good choice.